Description

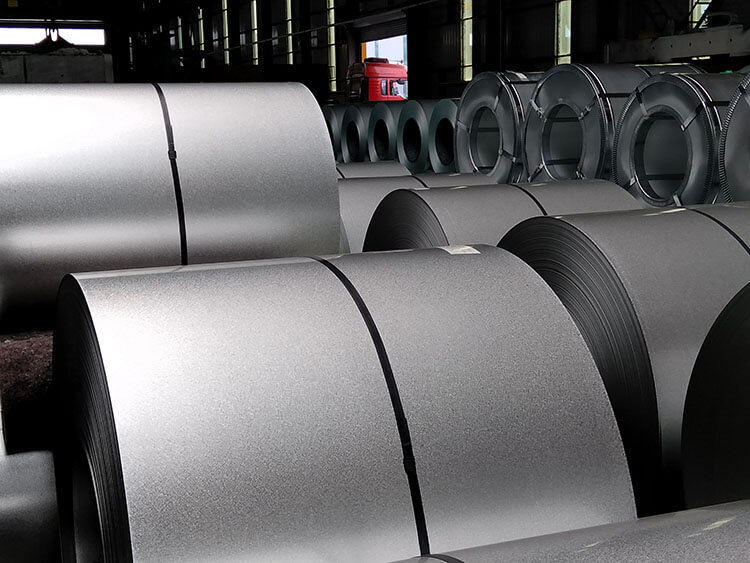

Aluzinc galvalume steel coils are a form of coated steel product that combines aluminum’s corrosion resistance with zinc’s sacrificial properties. These coils are made from a steel substrate that has been coated with an alloy of aluminum (55%), zinc (43.5%), and silicon (1.5%). The Aluzinc coating provides high corrosion resistance, making the steel coils appropriate for a wide range of outdoor applications and extreme conditions. They provide excellent durability, heat resistance, and thermal reflectivity. Aluzinc galvalume steel coils are widely utilized in building applications such as roofing, cladding, and siding. They are also used in the production of appliances, automobile parts, and other applications that demand tough, corrosion-resistant steel.

Advantages

Aluzinc galvalume steel coils have several distinguishing properties, which lead to their extensive use in a variety of industries. The following are the essential properties of aluzinc galvalume steel coils:

Corrosion Resistance

Aluzinc galvalume steel coils are more corrosion resistant than standard galvanized steel coils. The aluminum in the coating functions as a protective barrier, while the zinc serves as a sacrificial layer, adding an extra layer of corrosion resistance. This mixture prevents rust formation and increases the life of steel coils, especially in extremely corrosive situations like coastal areas or industrial settings.

High Heat Resistance

Aluzinc galvalume steel coils are extremely heat resistant, allowing them to survive high temperatures without substantial structural changes. This property makes them appropriate for applications involving heat or thermal cycling, such as roofing in hot climes or industrial equipment subjected to high-temperature processes.

Formability and Workability

Aluzinc galvalume steel coils are extremely formable, allowing for easy shaping without cracking or fracture. This feature makes them suitable for a variety of production procedures like bending, roll forming, and stamping. They can be formed into a variety of forms and profiles to fulfill individual design needs.

Aesthetic versatility

The smooth, glossy surface of Aluzinc galvalume steel coils allows for aesthetic versatility. They can be coated in a variety of colors, coatings, and textures, providing for unique solutions to match architectural designs and personal tastes. This feature makes them popular for roofing, cladding, and other applications requiring visual appeal.

Lightweight yet Strong

Despite their lightweight design, Aluzinc galvalume steel coils provide exceptional strength and longevity. This feature makes them ideal for applications where weight reduction is important, such as automotive production and construction. The lightweight design also allows for easier handling and installation, lowering labor and transportation expenses.

Longevity and Low Maintenance

Aluzinc galvalume steel coils are long-lasting and require little maintenance. The combination of aluminum and zinc in the coating increases resistance to corrosion, weathering, and wear, minimizing the need for frequent repairs or replacements. This property translates into cost savings and better durability in a variety of applications.

Environmental Sustainability

Aluzinc galvalume steel coils are eco-friendly. Aluminum and zinc are both recyclable materials, therefore using these coatings helps to ensure the product’s overall sustainability. Recycling steel and coating materials when they reach the end of their useful life helps to conserve resources and minimize waste.

These specific qualities make Aluzinc galvalume steel coils an excellent choice for a variety of industries, including construction, automotive production, and appliances. Their corrosion resistance, heat resistance, formability, strength, beauty, lifespan, and environmental sustainability combine to provide a dependable and adaptable solution for a wide range of industries.

Specs

| Standard | ASTM A792/A792M, JIS G 3321, EN 10346 |

| Grade | DX51D+AZ ASTM a792 |

| Alu-Zinc Coating | 20-275G |

| Thickness | 0.10-2.0mm |

| Width | 5-1250 mm |

| Coil ID | 508/610mm |

| Coil weight | 3-8tons |

| Surface Structure | Mini/Big Spangle |

| Surface Treatment | Anti-Finger printing ,Chromated, oiled/ non-oiled |

| Package | standard export package (Detailed picture is as follows) |

| Hardness | soft (normal), hard, full hard(G300-G550) |

| HS code | 7210610000 |

| Country of origin | China |

| Business type | Supplier and manufacturer |

Application

As previously said, Aluzinc galvalume steel coils have a wide range of applications across numerous sectors due to their exceptional properties. The following are some frequent applications for Aluzinc galvalume steel coils:

Roofing

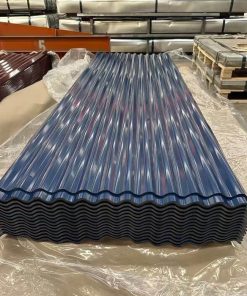

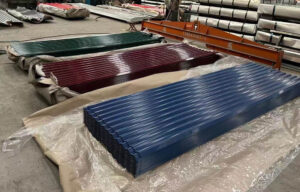

Aluzinc galvalume steel coils are commonly used for roofing in residential, commercial, and industrial buildings. They have exceptional corrosion resistance, providing long-term protection from environmental elements like rain, snow, and UV radiation. Coils can be molded into a variety of profiles, such as standing seam, corrugated, and tile profiles, allowing for greater design and installation versatility. Aluzinc galvalume steel coils are lightweight and durable, making them simple to handle and install.

Cladding and Siding

Aluzinc galvalume steel coils are extensively used for cladding and siding in constructions. They give a stylish and long-lasting outside surface while shielding the underlying structure from moisture, wind, and other environmental elements. The coils are available in a variety of colors and finishes, allowing for a diverse range of design possibilities. Aluzinc galvalume steel coils resist fading, chalking, and cracking, resulting in a long-lasting and low-maintenance cladding option.

Automotive Industry

The automotive industry uses Aluzinc galvalume steel coils for a variety of components. Coils are used in the manufacture of vehicle body panels such as hoods, fenders, doors, and roofs. Aluzinc galvalume steel has a high strength-to-weight ratio, which contributes to increased fuel efficiency and vehicle performance. Furthermore, the coils’ corrosion resistance protects against rust and improves the life of automobile components.

Appliances

Aluzinc galvalume steel coils are frequently used in appliance manufacture due to their visual appeal, durability, and corrosion resistance. They are applied to the exteriors of appliances such as refrigerators, stoves, washing machines, and air conditioners. The coils provide a smooth and visually appealing finish, which improves the overall appearance of the appliances. They also protect against moisture and other environmental variables, resulting in long-term endurance.

Building

Aluzinc galvalume steel coils are widely used in the building industry for a variety of structural purposes. They are utilized in the production of beams, columns, purlins, trusses, and other components. The coils’ great strength and longevity allow them to endure huge loads and structural stresses. Their corrosion resistance enables long-lasting performance, even in hostile environments. Aluzinc galvalume steel coils are commonly utilized in residential and commercial construction projects.

Industrial Applications

Aluzinc galvalume steel coils are used in a variety of industrial applications. They work in the manufacturing of storage tanks, ductwork, industrial roofing, and industrial equipment. The coils’ corrosion resistance and endurance make them ideal for usage in harsh industrial locations such as chemical processing plants, manufacturing facilities, and warehouses.

Solar Panels

Aluzinc galvalume steel coils are used in the solar sector to create mounting systems and frames for solar panels. The coils have high strength and corrosion resistance, making them perfect for outdoor applications. They provide a strong and resilient platform for solar panels, ensuring long-term performance under harsh weather conditions.

These are some of the primary uses for Aluzinc galvalume steel coils. Their combination of corrosion resistance, strength, formability, and aesthetic appeal makes them highly adaptable and appropriate for a wide range of industries and applications.

Galvanized Coils (Sheets/Strips)

Galvanized Coils (Sheets/Strips) Galvalume Coils (Sheets/Strips)

Galvalume Coils (Sheets/Strips) PPGI/PPGL Coils

PPGI/PPGL Coils Corrugated Roofing sheets

Corrugated Roofing sheets Hot Rolled Coils (Sheets/Strips)

Hot Rolled Coils (Sheets/Strips) Cold Rolled Coils (Sheets/Strips)

Cold Rolled Coils (Sheets/Strips) Aluminum Coils (Sheets)

Aluminum Coils (Sheets) Tinplate Coils

Tinplate Coils