Description

PPGI, also known as pre-coated steel, coil coated steel, and colour coated steel, stands for Pre-Painted Galvanised Iron. Galvanized Iron is obtained when coated steel is continuously hot dipped to form Zinc of purity greater than 99%. The galvanized coating provides cathodic and barrier protection to the base steel. PPGI is made by painting of Galvanized Iron prior to formation as it significantly reduces corrosion rate of zinc. Such a corrosion protection system makes PPGI attractive for structures designed to last a long time in aggressive atmospheres.

PPGL is shor for prepainted galvalume coils, which is coated with a mix of aluminum, zinc, and silicon. The usual composition of galvalume coating is 55% aluminum, 43.4% zinc, and 1.6% trace elements.PPGL Sheets are prepared by combining the strength of steel with anti-corrosive capabilities of a metal coating like Zinc or Aluminium. It is exceptionally resistant to weather and environmental degradations and can be punched, pressed, roll-formed, or joined in any way possible per requirement.

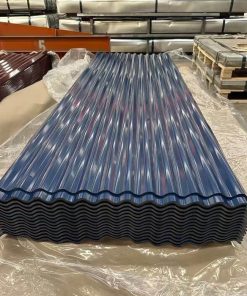

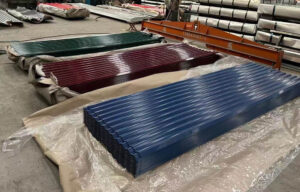

All the colors on the ral chart can be customized as you desire and expectation. and paint film can also be made as your requirement to promise the high quality and long-term working life of the roofing sheets.

Advantages

Acid rain resistance:

Coating protection mechanism: PPGI and PPGL are easy to form acid rain in the environment of high-level industrial emissions or pollutants. Acid penetration will form on the surface of precoated steel and accelerate corrosion, forming blistering, peeling and other phenomena.

• UV resistance:

Coating protection mechanism: under the condition of ultraviolet or strong sunlight, the precoated plate will be powdered and denatured, which will show discoloration and loss of luster, and quickly lose the coating.

• Moisture and heat resistance:

Coating protection mechanism: in hot and humid environment, the high osmotic pressure of water vapor will accelerate the penetration, form the denaturation of the coating film, and then corrode the substrate, and bubble and peeling will occur.

• Low temperature resistance:

Coating protection mechanism: most of the coatings can maintain stable processing performance above 0 ° C. However, when the temperature is lower than 20-40 ° C in the cold area, the ordinary coatings will become brittle, bend or even fall off, so the protective effect is completely lost.

Specs

| Standard | AISI,ASTM,GB,JIS | COLOR | All RAL color can be made |

| Material(Grade) | SGCC,SGCH,G350,G450, G550,DX51D,DX52D,DX53D |

Substrate type | Galvanized / galvanized steel |

| Coating process type | Front: double coated&double drying. | ||

| Hardness | HRB60-110 | ||

| Width | 5-1250mm | Thickness | 0.10-1.2mm |

| Front Primer | PU or Epoxy 5μm | Zinc coating | Z30-Z275G |

| Back Primer | PU or Epoxy 2-5μm | Surface treatment | Protective film can be applied |

Application

PPGI / PPGL Coils have a wide application as below:

- CONSTRUCTION: PPGI and PPGL are widely used in the construction industry for roofing, walls, sandwich panels, gutters, and flashing. Its beauty, durability, and corrosion resistance make it the preferred choice for residential and commercial construction.

- Automotive:PPGI and PPGL are used in the automotive industry to manufacture parts such as body panels, doors, hoods, fenders, and trim components. Pre-painted surfaces are attractive and protect against corrosion, enhancing the vehicle’s appearance and extending its service life.

- Appliances: PPGI and PPGL Sheet can be applied to producing household appliances such as refrigerators, washing machines, ovens, and air conditioners. The pre-painted surface can be customized to match the desired color and style of the appliance, enhancing its visual appeal.

- ELECTRICAL EQUIPMENT: PPGI and PPGL Sheet are used in the manufacture of electrical cabinets, switch boxes, control panels, and electrical enclosures. Its corrosion resistance and durability make it suitable for protecting electrical equipment from environmental factors and ensuring long-term performance.

- Furniture: PPGI and PPGL is used in the furniture industry to produce various items such as cabinets, shelves, tables, and filing cabinets. It is available in multiple color options and offers durable and attractive finishes.

- Transportation: PPGI and PPGL are used in transportation areas such as containers, trailers, and cargo vehicles. The pre-painted surface enhances the appearance and protects against corrosion during transport and exposure to different weather conditions.

- AGRICULTURAL EQUIPMENT: PPGI and PPGL manufacture agricultural equipment, including grain bins, storage tanks, and farm buildings. The corrosion resistance and longevity of the pre-painted surfaces help protect the equipment and ensure its functionality in the agricultural environment.

Galvanized Coils (Sheets/Strips)

Galvanized Coils (Sheets/Strips) Galvalume Coils (Sheets/Strips)

Galvalume Coils (Sheets/Strips) PPGI/PPGL Coils

PPGI/PPGL Coils Corrugated Roofing sheets

Corrugated Roofing sheets Hot Rolled Coils (Sheets/Strips)

Hot Rolled Coils (Sheets/Strips) Cold Rolled Coils (Sheets/Strips)

Cold Rolled Coils (Sheets/Strips) Aluminum Coils (Sheets)

Aluminum Coils (Sheets) Tinplate Coils

Tinplate Coils