Description

Tinplate(SPTE) is a common name for electroplated tin steel sheets, which refers to cold-rolled low-carbon steel sheets or strips coated with commercial pure tin on both sides. Tin mainly acts to prevent corrosion and rust. It combines the strength and formability of steel with the corrosion resistance, solderability and aesthetic appearance of tin in a material with corrosion resistance, non-toxicity, high strength and good ductility.Tin-plate packaging has a wide range of coverage in the packaging industry because of its good sealing, preservation, light-proof, ruggedness and unique metal decoration charm. Because of its strong antioxidant, diverse styles and exquisite printing, tinplate packaging container is popular with customers, and widely used in food packaging, pharmaceutical packaging, commodity packaging, instrument packaging, industrial packaging and so on.

Advantages

1. Optimal Protection for Contents

Electrolytic tinplate, including tinplate steel sheets and tinplate metal, provides superior protection for the contents of metal packaging containers. The tin coating process creates a robust barrier that guards against moisture, oxygen, and light, which is essential for maintaining the quality of products. This protective feature is crucial for metal food packaging and beverage cans, where preserving freshness and preventing spoilage are paramount. Tinplate’s corrosion resistance and rust protection make it an excellent choice for safeguarding contents from environmental factors and extending the shelf life of packaged goods.

2. Extended Shelf Life

The extended shelf life provided by electrolytic tinplate is a significant advantage in metal packaging solutions. By preventing the ingress of air and moisture, tinplate packaging materials, such as tinplate coil stock and tinplate sheets, help maintain product stability and freshness. This is particularly important for food and beverage metal packaging, where reducing spoilage and extending shelf life contribute to decreased waste and enhanced consumer satisfaction. The effectiveness of tinplate in preserving product quality underscores its value in packaging applications.

3. Enhanced Product Safety

Product safety is a critical consideration in metal packaging, and electrolytic tinplate excels in this regard. Tinplate, including tin-coated steel sheets and tinplate coil stock, is non-reactive, ensuring that it does not leach harmful substances into the packaged contents. This non-reactivity is vital for metal packaging used in food, beverages, pharmaceuticals, and cosmetics. The tinplate surface treatment process ensures that the packaging maintains its integrity and safety, adhering to stringent quality standards in the metal packaging industry.

4. Versatility in Design and Form

Electrolytic tinplate offers exceptional versatility in metal packaging design. It can be manufactured into various forms, including tinplate sheets, tinplate coils, and tinplate roll stock. This flexibility allows for the creation of diverse container shapes and sizes, from standard metal cans to custom metal packaging solutions. The adaptability of tinplate supports innovative metal packaging design and applications across different sectors, including food and beverage, cosmetics, and industrial metal packaging.

5. Recyclability and Sustainable Metal Packaging

A notable benefit of electrolytic tinplate is its recyclability, which aligns with sustainable metal packaging practices. Tinplate packaging materials can be recycled indefinitely without losing quality, supporting eco-friendly metal packaging initiatives. The recycling process for tinplate, including tinplate production and tinplate sheet metal recycling, contributes to global sustainability efforts by reducing waste and conserving resources. This makes tinplate an attractive option for manufacturers seeking to enhance their environmental footprint and promote sustainable metal packaging solutions.

Specs

| Electrolytic Tinplate Sheet | |

| Standard | JIS G 3303-2002, ASTM A623M-2002, DIN EN 10203-1991 |

| Grade | MR ,SPCC,SPHC,Q195, S08AL. |

| Material Origin | BAO(BAOWU) Steel |

| Tin Coating | 2.0/2.0, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4 /8.4 |

| Tin Weight | 1.1G/M2-8.4G/M2 |

| Surface Finish | Bright Finish, Stone Finish, Silver Finish, Matte Finish |

| Temper | T1, T2, T2.5, T3, T4, T5, DR-8, DR-7M, DR9 |

| Thickness | 0.12-0.55MM |

| Width | 20-1250MM |

| Coil Weight | 3-5MT/Coil or Customized |

| Coil Inner Diameter | 508MM or 610MM |

| Package | Standard Seaworthy Exporting Packing |

| MOQ | 25MT |

| Capacity | 6000MT/Month |

| Transport Type | Vessel Container, Vessel Bulk ,Railway Container,Railway Wagon |

| Loading Port | Tianjin, Qingdao, Ningbo, Shanghai and other port |

| Delivery Time | 25-30 Days after Receiving the Deposit |

| Terms of Trade | EXW,FOB, CFR, CIF |

| Terms of Payment | TT and Irrevocable LC at Sight |

| Code | Classification | Specific Finishes |

| B | Bright Finish | The luster surface are provided by a flow-brightened tin coating on smooth finished steel base metal. |

| R | Stone Finish | The luster surface are provided by a flow-brightened grindstone-pattern tin coating on steel base metal. |

| S | Silver Finish | The luster surface are provided by a flow-brightened tin coating on a coarse dull finish steel base metal. |

| M | Matte Finish | A dull surface provided by an unmelted coating on dull finished steel base. |

Application

- Food cans

- Beverage cans and metal caps

- 18-liter cans

- Candy tins

- Spray cans

- Tin plate toys

- Electric and electronic parts

- Bearing parts(sealing parts)

Tin plate has found itself integrated into various aspects of our daily lives. Since 1934, when we became the first privately owned tin plate manufacturer in Japan, we have been providing high-quality tin plate to meet our customers’ needs. Our high-quality tin plate, produced using traditional techniques in state-of-the-art facilities, is highly appreciated by our customers both in Japan and overseas.

Galvanized Coils (Sheets/Strips)

Galvanized Coils (Sheets/Strips) Galvalume Coils (Sheets/Strips)

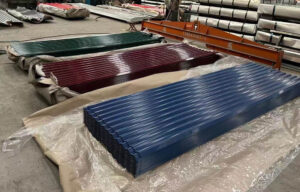

Galvalume Coils (Sheets/Strips) PPGI/PPGL Coils

PPGI/PPGL Coils Corrugated Roofing sheets

Corrugated Roofing sheets Hot Rolled Coils (Sheets/Strips)

Hot Rolled Coils (Sheets/Strips) Cold Rolled Coils (Sheets/Strips)

Cold Rolled Coils (Sheets/Strips) Aluminum Coils (Sheets)

Aluminum Coils (Sheets) Tinplate Coils

Tinplate Coils