Description

Hot Rolled Carbon Steel Coil is a type of steel coil that is made of carbon steel, which is primarily composed of iron and carbon. The hot rolling process involves heating the steel above its recrystallization temperature and then passing it through rollers to reduce its thickness and shape it into a coil.

This process results in a material with a smoother surface finish and tighter tolerances than cold rolled steel. The carbon content of hot rolled carbon steel coil is typically around 0.05-0.25%, which provides good weldability and ductility. Other elements such as manganese, silicon, and sulfur are also present in small amounts to improve the steel’s mechanical properties.

Advantages

-

Strength and Durability:

Hot rolled steel coils from a steel plant in India are known for their exceptional strength and durability. The heating and rolling process aligns the grain structure of the steel, resulting in improved toughness and resistance to deformation. This makes them suitable for demanding applications in construction projects, where strength is paramount.

Cost-Effectiveness:

One of the major advantages of hot rolled steel coils from our steel manufacturing plant is their cost-effectiveness. The manufacturing process is relatively simple compared to other methods, which helps in keeping production costs down. Builders and manufacturers can benefit from this cost advantage without compromising on quality.

Versatility:

Hot rolled steel coils come in a variety of grades and thicknesses, making them highly versatile. Whether it’s for structural beams, pipelines, or automotive parts, hot rolled steel can be tailored to meet specific requirements. This versatility ensures that builders and manufacturers have access to the right material for their needs.

Improved Machinability:

Unlike cold rolled steel, which undergoes additional processing, hot rolled steel coils retain a scale layer on the surface. This scale layer acts as a lubricant during machining, resulting in improved machinability and reduced tool wear. This is particularly advantageous in industries where precision is crucial.

Specs

| Product Name | Hot Rolled Coils, Carbon Steel Coils |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

| Material | Q195, Q215,Q235,Q345,ST37, A36,45# ,16Mn, etc |

| Thickness(mm) | Hot Rolled Thickness:2.75mm-100mm Cold Rolled Thickness:0.2mm-3mm As Your Request |

| Width(mm) | 5mm-1500mm, As Your Request |

| Technique | Hot rolled |

| Surface | Bare,Black,Oiled,Shot Blasted,Spray Paint,Coated,Galvanized,or as Your Request |

| Coil ID | 508-610mm or as per your request |

| Coil Weight | 2~20 Tons or as per your request |

| Application | Construction, machinery manufacturing, container manufacturing, shipbuilding, bridges, etc. |

| Packing | Standard Export packing(Plastic film in the first layer,second layer is Kraft paper. Third layer is galvanized sheet) |

Application

Construction and infrastructure: Hot rolled coils are used in the construction of buildings, bridges, highways, and other infrastructure projects. They are used for structural components, such as beams, columns, and structural steel frames.

Manufacturing and fabrication: Hot rolled steel coils are used as raw material in the manufacturing and fabrication of various products, including automotive parts, machinery, appliances, pipes, and tubes.

Energy and transportation: Hot rolled coils find applications in the energy and transportation sectors, such as in the production of oil and gas pipelines, railroad tracks, and shipping containers.

Agricultural equipment: Hot rolled steel coils are used in the manufacturing of agricultural equipment, such as tractors, tillers, and harvesters.

General engineering: Hot rolled coils are utilized in a wide range of general engineering applications, including storage tanks, pressure vessels, and industrial machinery.

Hot rolled steel coils offer advantages such as cost-effectiveness, availability in various grades and sizes, and good formability. They are a versatile material used in diverse industries due to their strength, durability, and ease of fabrication.

Galvanized Coils (Sheets/Strips)

Galvanized Coils (Sheets/Strips) Galvalume Coils (Sheets/Strips)

Galvalume Coils (Sheets/Strips) PPGI/PPGL Coils

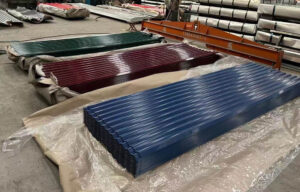

PPGI/PPGL Coils Corrugated Roofing sheets

Corrugated Roofing sheets Hot Rolled Coils (Sheets/Strips)

Hot Rolled Coils (Sheets/Strips) Cold Rolled Coils (Sheets/Strips)

Cold Rolled Coils (Sheets/Strips) Aluminum Coils (Sheets)

Aluminum Coils (Sheets) Tinplate Coils

Tinplate Coils